Related courses

Programmable Logic Controller

Instructor: Sonepar India

Language: English

Enrolled Learners: 19

Validity Period: 180 days

₹3000.00

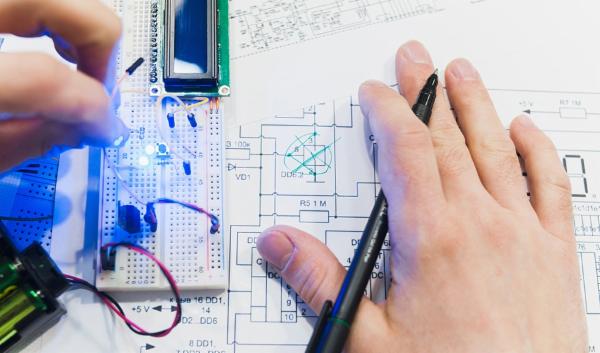

About Programmable Logic Controllers

Programming a PLC system provides the basic technical skills and knowledge necessary to work with programmable logic control systems typically found in an industrial or manufacturing environment. This interactive online course is designed to equip the novice with little or no prior PLC programming experience with the basic tools necessary to create a complete PLC program using ladder logic common to most current platforms. Upon completion, you will be able to use programmable logic controllers to solve machine and process problems. A systems approach to PLC programming training is used because the programmable logic controller is one major component of larger manufacturing systems.

A Programmable Logic Controller (PLC) is a device that is capable of being programmed to perform control functions. The first PLC was introduced in the late 1960s to replace relay logic controls in the automotive industry. Compared to relay logic controls, the PLC's advantages include easy programming and installation, high control speed, hardware and software security, network compatibility, troubleshooting and testing convenience, and high reliability.

PLCs are currently used widely in industrial and commercial environments. They can be found in almost any manufacturing facility. There are several manufacturers of PLCs. While the instruction formats may not be the same for different brands, the hardware structures and programming concepts are very similar. This course covers PLC hardware structure, input/output modules, software, and programming.

Scope of Programmable Logic Controllers

If you use PLCs or are thinking of doing so, you may consider them to be a mature technology with little room for improvement as they’ve been around for nearly 50 years. But like their close counterparts in the world of consumer electronics, significant improvements continue with no end in sight, promising faster, smaller, and lower cost solutions.

The PLC’s hardened embedded processor, running a real-time proprietary operating system, has proven to be a mainstay of the industrial automation world, fighting off all challengers to its supremacy. Microsoft Windows-based open systems have made inroads but lag behind PLCs, a trend expected to continue as the PLC with its purpose-built hardware, specially designed software, and one-supplier support model remains a solid choice for many industrial control applications.

Benefits of Programmable Logic Controllers

1. Helps Minimize The Learning Curve

If you are working with PLCs, PLC training is a failsafe method to get ahead of the learning curve. Gone are the days when companies would hire engineers and teach them about PLC and PLC programming on the job.

Now, the manufacturers do not want to invest their PLC training resources and prefer hiring candidates with prior knowledge. This allows them to reduce the time-to-market and beat the competition.

2. Gain A Competitive Edge

The automation environment is constantly evolving with new developments that can help a company gain a competitive edge. However, as is with any technology, PLCs must have the capability to keep getting to run the risk of being obsolete.

But a PLC trained engineer will be able to understand the hardware and software advancements that make PLC an efficient, user-friendly, and cost-effective system for the organization.

3. Saves Time

More and more companies are now moving to the automation landscape to save time and resources. PLC training enables the engineer to incorporate the automation to certain processes that can help the organization save time and money.

4. Wide Range Of Career Options

A competent, PLC-trained engineer can find plenty of career options. It is a reasonable professional that offers huge potential in terms of job security and monetary benefits. Additionally, thanks to the dynamic environment, you will be working with a process that needs continuous development and improvement, giving you job satisfaction and ample growth scope!

Eligibility:

Program has the following eligibility criteria:

Graduation with minimum 50% marks

All the management and business related students, any student who want to join.

Certification:

1. Learn the major components of a Programmable Logic Controller (PLC);

2. Learn the functions of the CPU, input modules, and output modules in a PLC;

3. Be familiar with binary number and decimal number systems;

4. Be able to convert a binary number to decimal number and vice versa;

5. Learn basic logic functions: AND, OR, and NOT;

6. Be familiar with the operation and scan cycle of a PLC;

7. Learn bit instructions and their functions;

8. Be able to use bit instructions for PLC programming;

9. Learn timer instructions and their functions;

10. Be able to use timers for PLC programming;

11. Learn counter instructions and their functions; and

12. Be able to use counters for PLC programming.

.jpg)